- 22, Drive-In Tenaments, Ahmedabad, - 380054

Phone: +91-9825088388 | Email: [email protected] | Address: 22, DRIVE-IN TENAMENTS, AHMEDABAD, GUJARAT, INDIA - 380054

Timing Belts - Types & Application

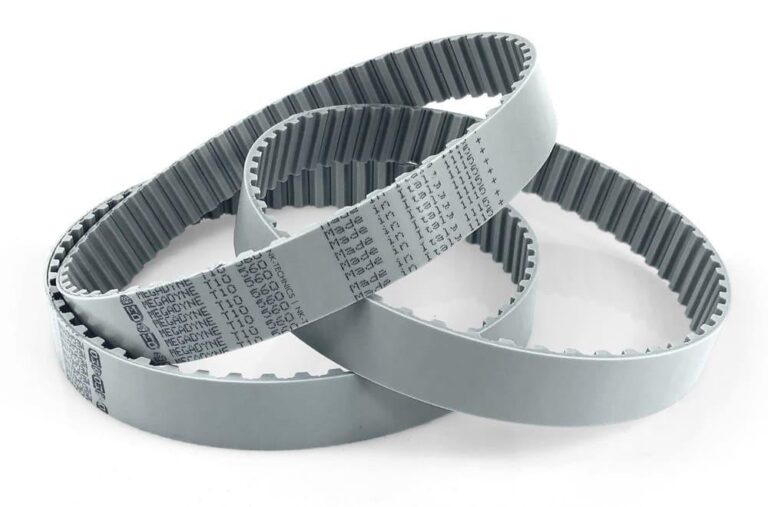

Rubber belt

PU Belt

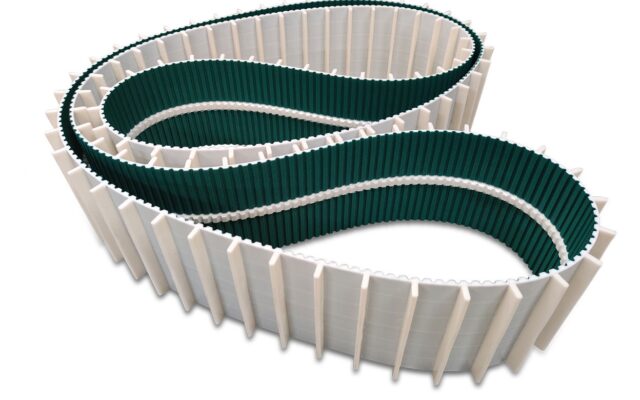

Profile Belt

Coated Belt

Power Transmission

Power Transmission

Conveying

Custom Application

HTD, GT2, GT3

Polychain Carbon

Imperial, RPP

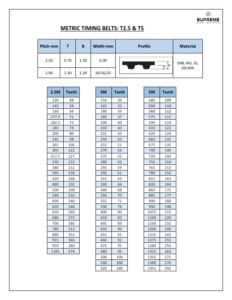

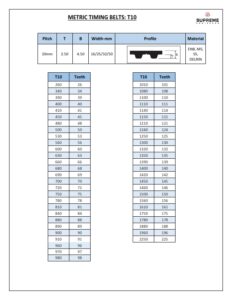

T5,T10,T20

AT5,AT10,AT20

With cleets

Double molded

Silicon or Neoprene coating

High temperature

FDA Approved

Rubber Belt Cutting Process

Timing Belts - Brands available

Gates

Fenner

Contitech

Syncroflex

Megadyne

Elatech

Key Features

Precision Timing

Our Timing Belts are designed with meticulous attention to detail, ensuring precise timing and synchronization of mechanical systems. This precision is crucial for maintaining optimal performance.

High Quality Materials

Crafted from top-quality materials, our Timing Belts are known for their durability and resistance to wear and tear. They are built to withstand the most challenging operating conditions, ensuring a long service life.

Low Noise & Vibration

Supreme Engineers Timing Belts are engineered for smooth and quiet operation. They minimize noise and vibration, providing a more comfortable and efficient working environment.

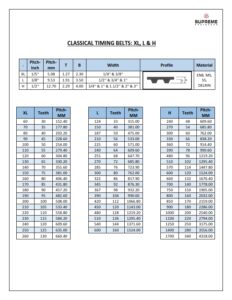

Wide Range of Options

We offer a comprehensive range of Timing Belts, including different widths, profiles, and tooth configurations, to suit various applications and industries.

Why Choose our Timing Belts

Improved Efficiency

By maintaining precise timing and reducing slippage, our Timing Belts enhance the efficiency of your machinery. This improved efficiency leads to energy savings and increased productivity.

Reduced Maintenance

The durability of our Timing Belts means less downtime and lower maintenance costs. You can rely on our belts to perform consistently over the long term.

Customization

We understand that one size doesn't fit all. That's why we offer customized Timing Belts to meet your specific requirements. Our team of experts will work closely with you to design belts tailored to your application.

Advantages

Minimal noise & vibrations, Precise motion with accurate timing, Low maintenance & clean operation, Constant velocity ratio, No slippage, High mechanical efficiency up to 98%, Resistant to abrasion and rust.

Applications

Automotive Engines, Elevators, Printers, CNC Machines, 3D printers, Textile Machinery, Medical Equipment, Packaging Machinery, Aerospace Applications, Robotics, etc.

Materials

A timing belt is made from Rubber, Neoprene, Polyurethane, Fiberglass Reinforment, Steel Reinforment, Nylon Frabic, EPDM, Polyester, etc.